No products in the cart.

HI8410 Dissolved Oxygen Controller with 4 to 20mA

฿41,195.00

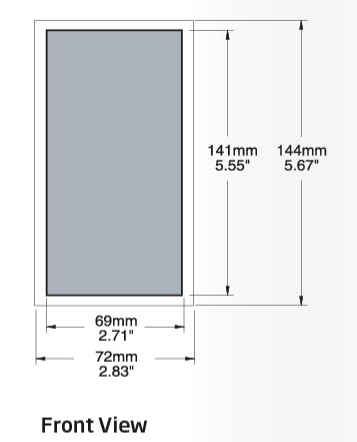

HI 8410 uses a Galvanic probe that typically requires less maintenance than a Polarographic style making it ideal for long term monitoring.

2 in stock

SKU: HI8410

Categories: วัดออกซิเจนในน้ำ, สินค้าทั้งหมด, อุตสาหกรรมทั่วไป, เครื่องควบคุมแบบต่อเนื่อง, แบบติดตั้ง

HI8410 คือตัวควบคุมออกซิเจนละลายน้ำแบบติดตั้งบนแผง ซึ่งใช้เพื่อรักษาและตรวจสอบความเข้มข้นของ DO ในการใช้งานกระบวนการทางอุตสาหกรรมที่หลากหลาย HI8410 ใช้โพรบแบบกัลวานิกซึ่งโดยทั่วไปต้องการการบำรุงรักษาน้อยกว่าแบบโพลาโรกราฟี ทำให้เหมาะอย่างยิ่งสำหรับการตรวจสอบในระยะยาว

ผู้ใช้จะปรับค่าที่ตั้งไว้สำหรับการควบคุมการเปิดใช้งานรีเลย์ด้วยตนเอง รีเลย์สัญญาณเตือนยังสามารถปรับได้ด้วยตนเอง และขึ้นอยู่กับพิกัดความเผื่อจากจุดที่ตั้งโปรแกรมไว้ การสอบเทียบเป็นจุดที่ตั้งไว้เดียวและสามารถทำได้ในสารละลายที่ไม่มีออกซิเจน

Extended range to 50 mg/L (ppm)

- Manual single point calibration

- Selectable 0-20 or 4-20 mA output

- Low maintenance Galvanic DO probe

- Backlit LCD

- Operational mode LED indicators

- Transparent splash-proof cover included

The HI8410 is a panel mounted dissolved oxygen controller that is used to maintain and monitor the concentration of DO in a wide range of industrial process applications. The HI8410 uses a Galvanic probe that typically requires less maintenance than a Polarographic style making it ideal for long term monitoring.

The set point for controlling the activation of a relay is adjusted manually by the user. An alarm relay is also manually adjustable and is based upon a tolerance from the programmed set point. Calibration is single set point and can be done in zero oxygen solution.

The dosage mode: automatic, continuous ON or OFF and over dosage control by setting the overtime dosage trimmer. If the dosing relay remains continuously activated for more than the selected dosing time, the alarm relay is activated, the alarm LED will start blinking and the dosing relay will be deactivated. A jumper found on the rear panel can disable the “over time dosage” function.

“Automatic/Off/manual” dosing selection switch and LED on the front panel. In Automatic mode all the relays are controlled based on the measurement set point and alarm values. In OFF mode the dosing and alarm relays are always deactivated. The dosing LED is OFF (as relay status) and the ALARM LED is in accordance with the instrument set point, input reading, and ALARM. In ON (Manual) mode the dosing relay is always on. The alarm relay is still enabled. If an alarm occurs the dosing relay remains activated. If the over dose time exceeds the setting during manual mode, the alarm relay remains activated.

The D.O. probe is provided with a membrane covering the galvanic sensor and a built-in thermistor for temperature measurement and compensation.

Other features include: recorder output in 0-20 mA or 4-20 mA configuration, LED indicators which identify whether the controller is in operation mode or setup selection mode, overtime control function and hysteresis setting.

Order Information:

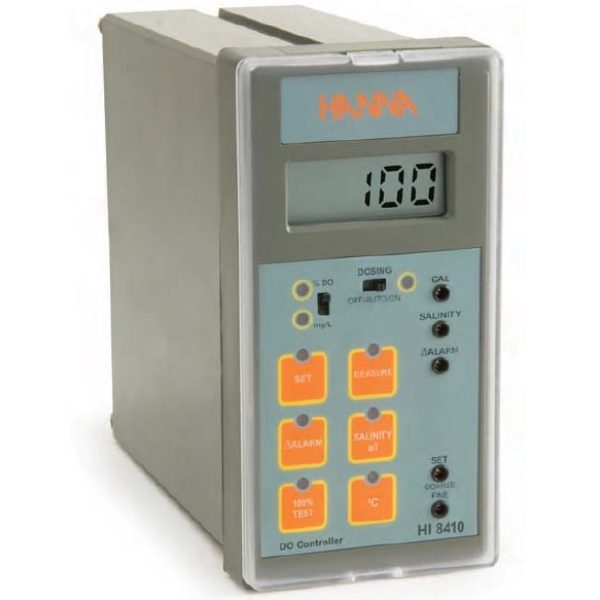

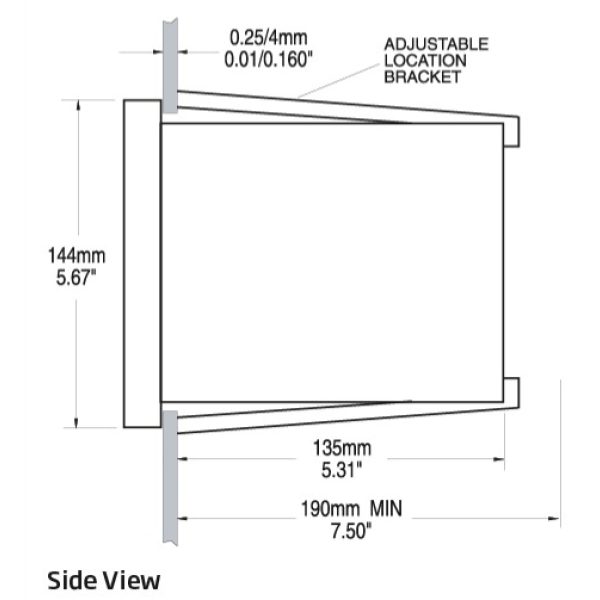

The HI 8410 is supplied complete with mounting brackets and instructions.

Product Manuals

![]() Manual: Download

Manual: Download

Specification :

| Range | 0.0 to 50.0 mg/L (ppm) O2 0 to 600 % O2 -5.0 to 50.0 °C |

|

| Resolution | 0.1 mg/L or 1% (O2) / 0.1 °C | |

| Accuracy @ 20°C | ±1% of reading (O2) / ±0.2 °C | |

| Calibration | manual, one point, in saturated air | |

| Temperature Compensation |

automatic, from -5 to 50°C (23 to 122 °F) | |

| Salinity Compensation | 0 to 51 g/L (resolution 1 g/L) | |

| Probe (not included) | HI 76410/4 with 4 m (13.1’) cable or HI 76410/10 with 10 m (32.8’) cable | |

| Recorder Output | 0 to 20 mA or 4 to 20 mA (isolated) | |

| Setpoint and Alarm Relay |

1, isolated, 2A, max. 240V, resistive load, 1,000,000 strokes | |

| Setpoint Range | 1 to 600 % O2; 0.1 to 50.0 mg/L (ppm) O2 | |

| Alarm Range | 1.0 to 5.0 mg/L (ppm) O2 | |

| Hysteresis Range | 0.5 to 2.4 mg/L (ppm) O2 | |

| Dosing Control | OFF/AUTO/ON with selection switch | |

| Over Dosing Control | adjustable, from 5 min to 60 min with knob or disable by wire strap – on rear panel | |

| Backlight | continuous on | |

| Power Supply | 115 VAC ±10% or 230 VAC ±10%; 50/60 Hz | |

| Enclosure | flame retardant ABS body and front panel; transparent splash-proof front cover | |

| Environment | -10 to 50°C (14 to 122°F); RH max 95% non-conndensing | |

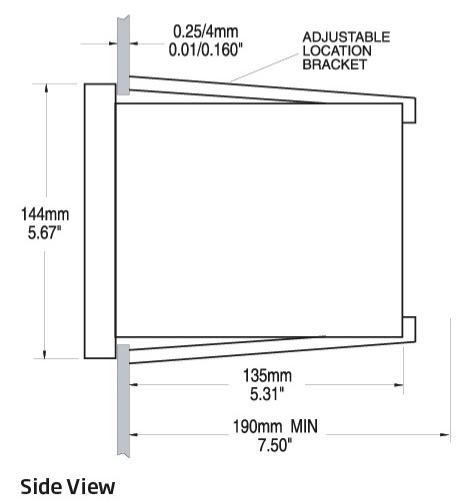

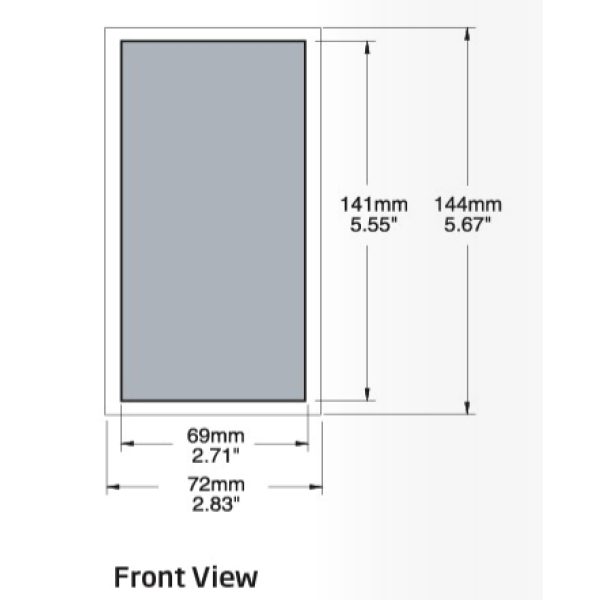

| Panel Cutout | 141 x 69 mm (5.6 x 2.7’’) | |

| Weight | 1 kg (2.2 lb.) |

Related products

สินค้าทั้งหมด

฿3,103.00

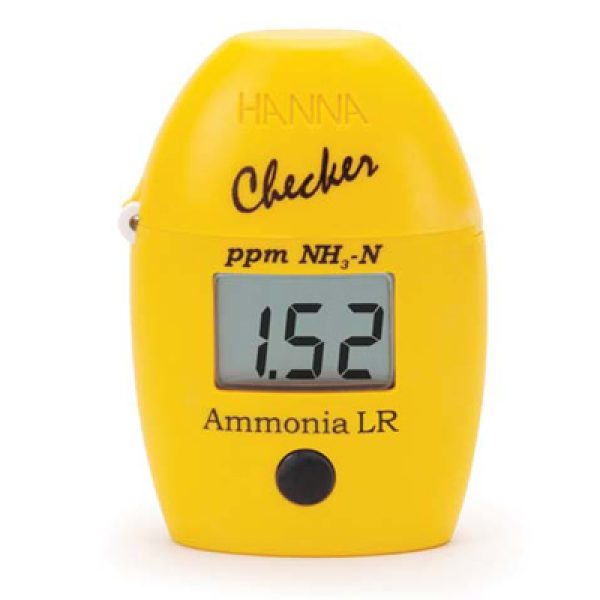

Range 0:00 to 3:00 ppm NH3-N | Nessler Method | 0.01ppm resolution

สินค้าทั้งหมด

฿3,103.00

Range 0 - 600 ppb NO2-N | EPA method 354.1 | Resolution 1 ppb

สินค้าทั้งหมด

฿3,103.00

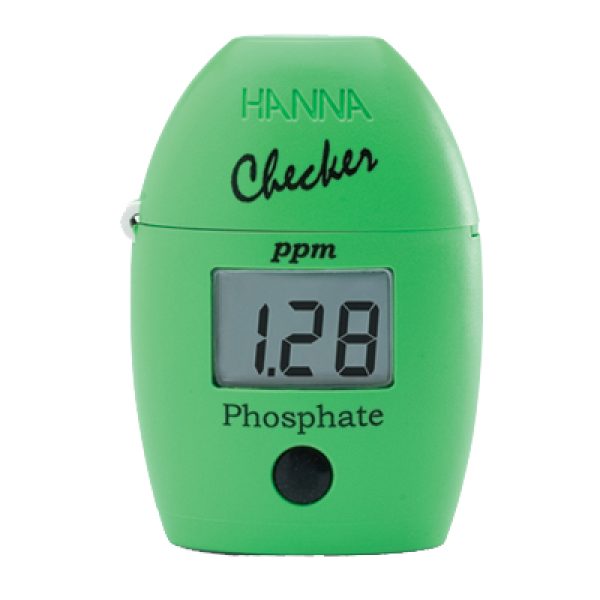

Range 0.0 - 12.5 ppm | DPD Method | Resolution 0.1ppm

สินค้าทั้งหมด

฿3,103.00

Range 0:00 to 2:00 ppm | ASTM D859 Method | 0.01ppm resolution

สินค้าทั้งหมด

฿3,103.00

Range 0:00 to 2:50 ppm | ascorbic acid method | Resolution 0.01ppm

สินค้าทั้งหมด

฿12,305.00

ช่วงการวัด 0.00-2.50ppm

สินค้าทั้งหมด

฿3,103.00

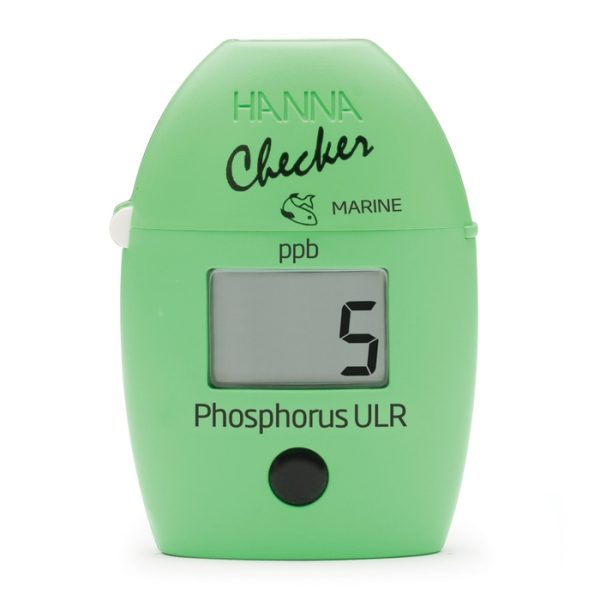

Range 0 - 200 ppb | ascorbic acid method | Resolution 1 ppb

สินค้าทั้งหมด

฿3,103.00

Range 0.00 - 9.99 ppm NH3-N | Nessler Method | 0.01ppm resolution